How to Conduct Effective Wear Testing for Product Durability?

In the pursuit of product durability, effective wear testing is crucial. Dr. Emily Hughes, a renowned expert in the field of material science, emphasizes, "Wear testing helps predict how products will perform under real-world conditions." This statement highlights the importance of rigorous testing protocols.

Wear testing involves subjecting materials to various stressors. This can include friction, abrasion, and impact. It helps identify weaknesses before products reach consumers. Often, results reveal unexpected failures, forcing designers to rethink their approaches. The process can unveil flaws that might otherwise go unnoticed.

Ultimately, wear testing is an iterative journey. Each test serves as a feedback loop. Designers and engineers must be ready for any surprises. Embracing this complexity can lead to stronger, more durable products in the market. Thus, understanding the principles of wear testing is essential for any product development team striving for excellence.

Choosing the Right Wear Testing Method for Your Product Type

Choosing the right wear testing method is crucial for product durability. The selection depends on the product type and intended use. For instance, textiles may require abrasion testing, while mechanical parts may need fatigue testing. Each method has its pros and cons.

Consider environmental factors when selecting a test. Temperature and humidity can alter results significantly. It’s vital to replicate real-world conditions as closely as possible. A method that works in a lab may not translate to field performance. This gap can lead to overestimating a product's durability.

Reflecting on past tests can provide insights. Maybe the chosen method was too simplistic. Or the prototype didn’t represent the final product accurately. Continuous improvement in wear testing approaches is essential. Embrace feedback and adapt methods accordingly for better results.

How to Conduct Effective Wear Testing for Product Durability?

| Testing Method | Product Type | Test Duration | Key Metrics | Typical Applications |

|---|---|---|---|---|

| Abrasion Testing | Textiles, Coatings | 1000 Cycles | Weight Loss, Visual Wear | Clothing, Upholstery |

| Impact Testing | Plastic, Foam | Immediate Failure | Energy Absorption, Cracks | Packaging, Safety Equipment |

| Fatigue Testing | Metals, Composites | 1 Million Cycles | Cycles to Failure, Deformation | Structural Components, Machinery |

| Environmental Testing | Electronics, Plastics | 72 Hours | Corrosion Resistance, Functionality | Outdoor Equipment, Electronics |

| Compression Testing | Foams, Rubbers | Varies depending on material | Stress and Strain | Mattresses, Packaging |

Understanding Key Metrics in Wear Testing for Durability Assessment

Wear testing is crucial for evaluating product durability. Various metrics inform this process, helping designers understand performance limits. One vital aspect is the wear rate, which quantifies material loss over time. A higher wear rate often indicates inadequate material choice or design flaws.

Another important metric is friction coefficient. This value affects how materials interact under stress. A low friction coefficient can lead to smoother operation. However, it might also result in premature failures. Understanding these balances is critical for effective wear testing.

Testing conditions are essential in obtaining reliable data. Variations in temperature and humidity can significantly influence results. These factors often require adjustments to test parameters. Moreover, maintaining consistent pressure during testing is vital. Fluctuations can skew wear rate outcomes, leading to misguided assessments. Each of these metrics is pivotal, yet they often provoke further questions about optimization. The key is recognizing that there's always room for improvement.

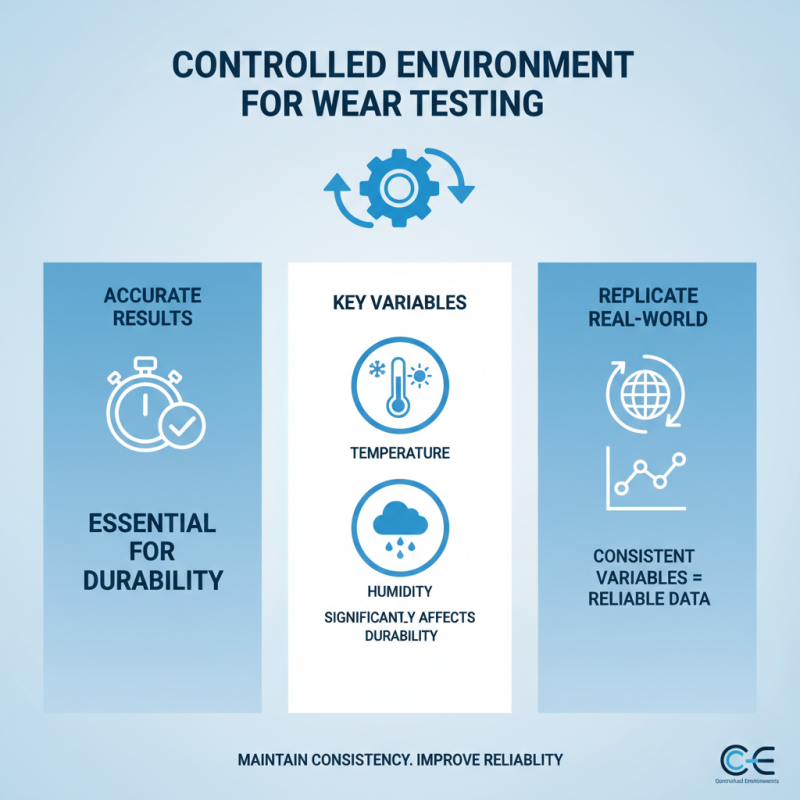

Establishing a Controlled Environment for Accurate Testing Results

Creating a controlled environment for wear testing is essential for accurate results. Temperature and humidity can significantly affect durability. Keeping these variables consistent during testing can help replicate real-world conditions.

Consider using a climate-controlled chamber. This setup can maintain stable conditions. It minimizes external factors that might skew your results. Regular calibration of the equipment is vital. A slight change in humidity can lead to significant differences over time.

When testing, document all conditions meticulously. Record temperature, humidity, and wear patterns. This data is invaluable for analysis. Reflect on your findings. Sometimes, unexpected results may reveal flaws in your product's design. Don't hesitate to adjust your testing parameters for clearer insights. Testing should evolve as you gather more data.

Interpreting Wear Test Data: Best Practices and Common Pitfalls

Interpreting wear test data is crucial for assessing product durability. Reliable data can be a game changer. Yet, many professionals face common pitfalls that obscure results. For instance, failing to control environmental factors can lead to misleading conclusions. Temperature and humidity variations often distort wear results.

Tips: Always monitor conditions closely. Use consistent testing environments.

Another common error involves inadequate sample size. Small sample sizes may not capture true wear patterns. A report from the Materials Testing Institute indicates that a sample size of at least 30 is ideal for statistical significance. Relying on faulty or incomplete data complicates interpretation and decision-making processes.

Tips: Conduct preliminary tests with varied samples. Expand your testing pool for clarity.

Lastly, acknowledge the limitations of your testing methods. Some tests may not simulate real-world usage. For instance, accelerated wear tests can underestimate durability. This divergence demands careful analysis of the situation for accurate insights and future product improvements.

Tips: Combine different testing methods for a comprehensive view. Always seek peer insights on your findings.

Comparative Analysis: Industry Standards for Wear Testing Procedures

Wear testing is crucial for assessing product durability. However, industry standards vary widely. Different sectors have established specific protocols. Understanding these can enhance testing outcomes.

For example, the automotive industry often uses standardized mechanical testing. This includes abrasion and impact tests. However, methods can sometimes overlook real-world conditions. A rubber component may excel in lab tests but fail in extreme weather.

Consumer electronics, on the other hand, focus on user experience. They conduct drop tests or scratch simulations. Still, many procedures lack clarity on long-term durability. It's vital to reassess these methods and adapt them to evolving materials and technologies. Test environments should replicate actual usage, not just theoretical limits. By revisiting existing standards, industries can produce products that truly endure.

Related Posts

-

Innovative Solutions for Precision Line Testers

-

Ultimate Guide to Choosing the Best Ball Rebound Tester for Your Needs

-

Maximizing Efficiency with Field Test Equipment Advantages for Your Business

-

How to Optimize Your Phone Testing Equipment for Accurate Performance Metrics

-

Understanding the Importance of Accurate Meter Test Equipment for Efficient Energy Management

-

What is Pile Testing Equipment and How Does it Ensure Structural Integrity