How to Test a Meter for Accuracy and Reliability?

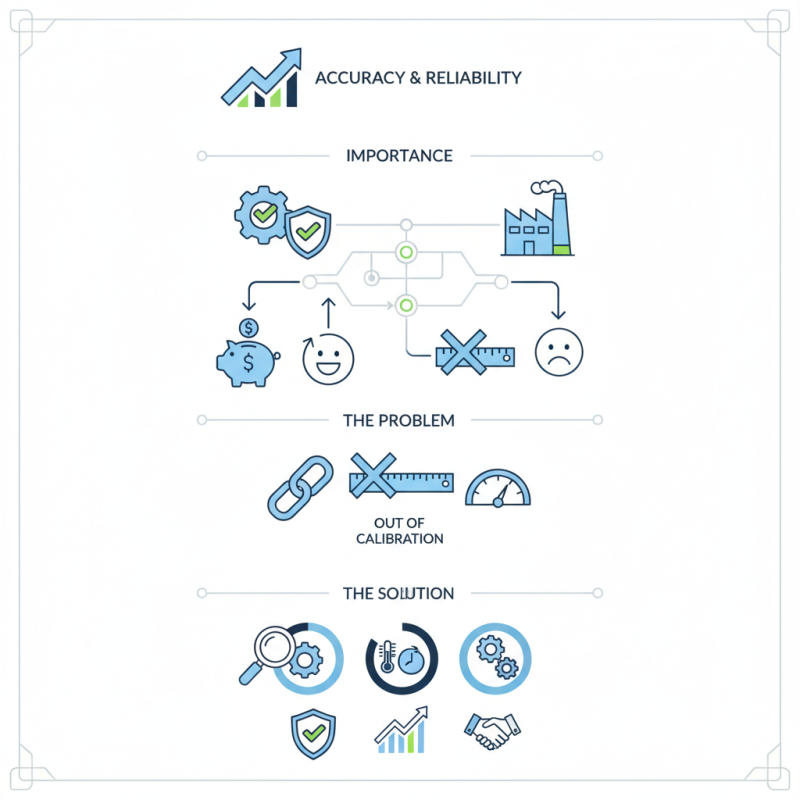

Testing meters for accuracy and reliability is crucial in many industries. Accurate measurements ensure that products meet standards. According to a recent report by the National Institute of Standards and Technology, ensuring testing meters perform correctly can reduce operational costs by up to 15%. Reliable meters can improve product quality and customer satisfaction.

However, many organizations overlook the importance of regular meter testing. This oversight can lead to significant errors over time. For instance, a study by the International Society for Measurement found that 30% of meters used in critical applications were found to be out of calibration. Regular testing can mitigate these risks.

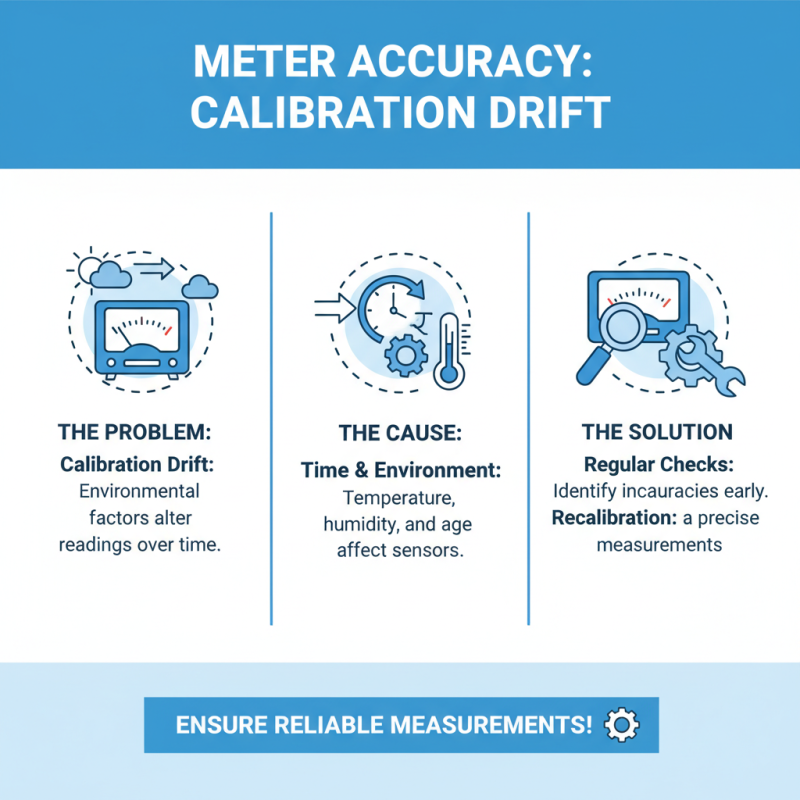

When testing meters, factors such as temperature, humidity, and wear need careful consideration. Different industries may have unique testing protocols. Still, ensuring that every "testing meter" operates within its specified limits is fundamental. Without competent testing, reliability is questionable, and businesses face more challenges than anticipated.

Understanding Meter Accuracy and Reliability Standards

Meter accuracy and reliability are crucial for various applications. These standards help ensure that measurements reflect true values, minimizing errors. When testing a meter, understanding these criteria is essential.

Accuracy refers to how closely a measurement aligns with its true value. Reliability, on the other hand, indicates how consistently a meter performs over time. A meter could be accurate but unreliable, leading to inconsistencies. For instance, repeated tests might yield varying results, prompting a need for recalibration.

Standards exist to guide manufacturers and users. However, not all meters meet these guidelines effectively. Some may pass initial accuracy tests but fail in practical applications. Regular checks and maintenance become vital to uphold reliability. It’s essential to question whether a meter delivers trustworthy measurements consistently, especially in critical tasks.

How to Test a Meter for Accuracy and Reliability? - Understanding Meter Accuracy and Reliability Standards

| Test Method | Description | Accuracy (%) | Reliability Rating | Frequency of Calibration |

|---|---|---|---|---|

| Direct Comparison | Comparing readings with a known standard | ±0.5% | High | Annually |

| Multi-Point Calibration | Testing at various points across the range | ±0.2% | Very High | Semi-Annually |

| Load Testing | Testing under specified load conditions | ±1.0% | Medium | Annually |

| Environmental Testing | Assessing performance under various environmental conditions | ±0.5% | High | Every Two Years |

| Drift Testing | Monitoring long-term stability and accuracy | ±1.5% | Medium | Every Six Months |

Tools and Equipment Needed for Testing Meter Accuracy

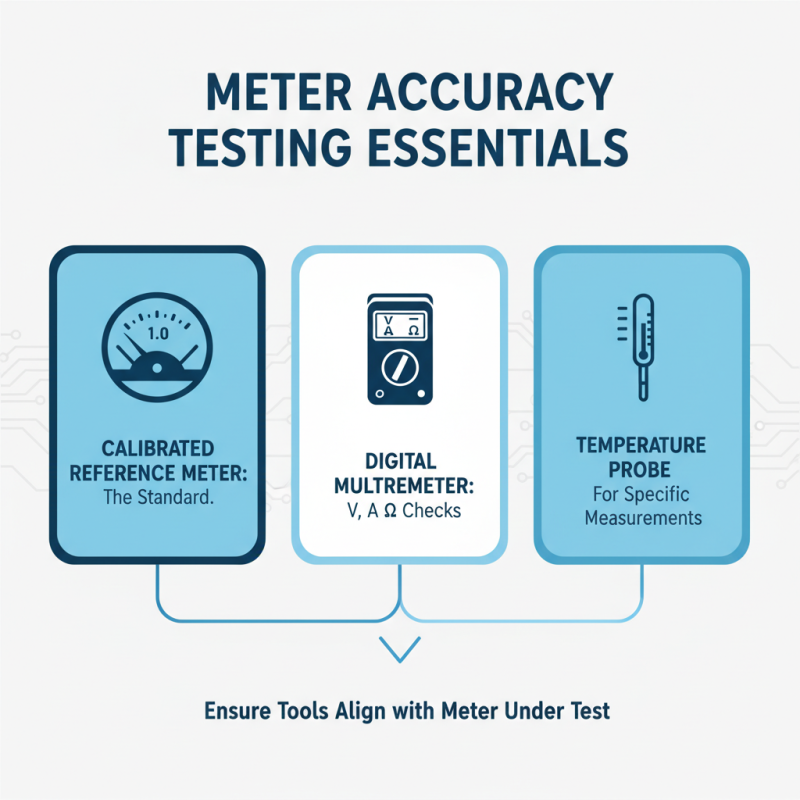

When testing a meter for accuracy, having the right tools is essential. A calibrated reference meter is fundamental. It serves as your standard. Digital multimeters can be helpful, too. They check voltage, current, and resistance accurately. Additionally, a temperature probe may be necessary depending on what you're measuring. These tools should align with the meter being tested.

Consider using insulated test leads. They enhance safety and accuracy during testing. A reliable power source is also required. This ensures the test meter receives the correct input. Sometimes, a variation in power supply can distort readings. Keep a notebook handy to record results. Tracking data is key, especially if inconsistencies arise.

Remember, the environment can affect measurements. Humidity and temperature fluctuations might skew results. Testing in a controlled space is often ideal. Take note of any unusual behavior during the test. It may point to issues within the meter itself. Meticulous attention to detail can make a difference in ensuring reliability.

Step-by-Step Procedure for Testing Meter Accuracy

Testing a meter for accuracy and reliability involves several essential steps. Start by gathering necessary equipment like calibration weights or standards. Ensure these standards are within the meter's range. Calibration weights should be certified and regularly maintained. According to the National Institute of Standards and Technology (NIST), regular testing can reduce errors by up to 30%.

Begin the procedure by setting the meter in a controlled environment. Temperature and humidity can affect results, so these should be monitored. For precise measurements, take readings multiple times. Analyze the data to assess the consistency of measurements. If results vary, further investigation into the meter's condition may be needed.

**Tips:** Always document your testing process. This creates a reference for future calibrations. Keep a log of any anomalies. Regular maintenance checks are crucial. They can prolong meter life and ensure accuracy. Remember that even high-quality meters may drift over time.

Lastly, create a routine schedule for testing. Regular assessments prevent issues from escalating. A proactive approach can save time and resources in the long run. Accuracy is not just a requirement; it's a responsibility that impacts performance and safety.

Analyzing Test Results and Assessing Meter Reliability

When testing a meter for accuracy, familiarity with industry standards is crucial. A recent report from the National Institute of Standards and Technology noted that up to 30% of meters can fail to meet accuracy standards during usage. This highlights the importance of regular testing and calibration. Results should be compared with reference meters that are known to be accurate. This process can identify inconsistencies that may arise from wear or environmental factors.

Understanding the reliability of a meter involves more than just initial testing. Consistent results over time are essential. Various studies have shown that operating conditions—like temperature and humidity—can impact readings significantly. For instance, a meter may show a 10% variance in accuracy at extreme temperatures. Such factors can lead to misleading conclusions if not regularly monitored. Ultimately, data trends should be assessed over time to ensure reliability before making critical decisions based on meter readings. Regular audits of performance can reveal discrepancies, prompting necessary adjustments.

Meter Accuracy and Reliability Test Results

Common Issues and Solutions in Meter Accuracy Testing

Testing a meter for accuracy is a crucial task. Various issues can arise during this process. One common problem is the calibration drift. Over time, environmental factors can change a meter’s readings. Regular checks can help identify this. If a meter consistently shows inaccurate results, recalibration is necessary.

Another issue is battery failure. A weak battery can lead to fluctuating readings. Users should routinely check battery life. If the meter has an option for power-saving modes, enable it. This can extend the battery life. It’s also important to replace batteries in a timely manner to prevent issues.

Dirt and corrosion can affect meter performance. Regular cleaning is vital, especially at connection points. A simple wipe with a cloth often suffices. However, users may forget this step. This can lead to unforeseen errors in measurements. Lastly, human error can’t be overlooked. Double-checking readings can save frustration later. Precision in handling meters ensures more reliable data.

Related Posts

-

Maximizing Efficiency with Field Test Equipment Advantages for Your Business

-

How to Choose the Best Phone Testing Equipment for Accurate Results

-

How to Optimize Your Phone Testing Equipment for Accurate Performance Metrics

-

Innovative Solutions for Precision Line Testers

-

Exploring the Role of Impact Equipment in Sustainable Construction Practices

-

Top 10 Essential Phone Testing Equipment for Quality Assurance Professionals