Revolutionizing Production: Top 5 Technical Specifications of the Best Automatic Assembly Machine

In the ever-evolving landscape of manufacturing, the role of Automation is becoming increasingly pivotal, particularly with the advancement of the Automatic Assembly Machine. As industries strive for efficiency, precision, and cost-effectiveness, these cutting-edge machines are revolutionizing production lines worldwide. This blog will explore the top five technical specifications that define the best Automatic Assembly Machines, showcasing how they enhance operational productivity and improve product quality. By understanding these key features, businesses can make informed decisions about investing in technology that not only meets their current needs but also positions them for future growth. Join us as we delve into the essential elements that make these machines indispensable in modern manufacturing.

Key Features Driving Efficiency in Automatic Assembly Machines

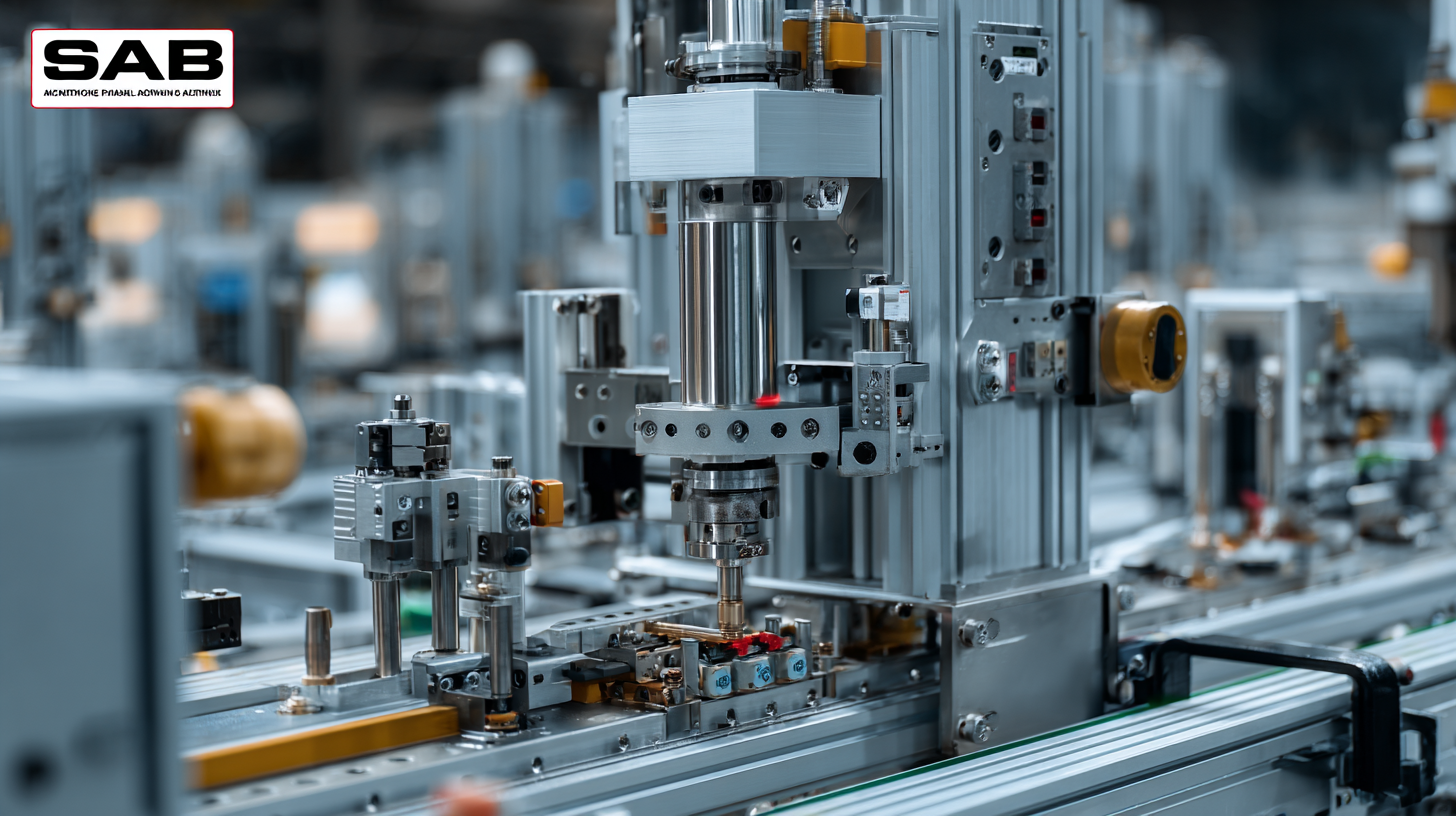

The rapid advancement in automation has transformed the manufacturing landscape, particularly through the optimization of production lines using automatic assembly machines. A key feature driving efficiency in these machines is their ability to enhance precision and reduce operational costs. According to a report from the International Federation of Robotics, companies utilizing advanced automation technologies, including automatic assembly systems, have realized a productivity increase of up to 30% in their assembly processes, reflecting the significant advantages of incorporating these cutting-edge solutions.

Additionally, the integration of smart technology, such as IoT (Internet of Things) and AI (Artificial Intelligence), into assembly machines has revolutionized operational efficiency. A study by McKinsey & Company highlights that companies implementing AI-driven assembly processes can optimize decision-making in real-time, reducing errors by 40% and increasing throughput by as much as 25%. These remarkable improvements not only streamline production but also enable manufacturers to adapt rapidly to market demands, ensuring competitiveness in an ever-evolving industry.

Furthermore, the flexibility of automatic assembly machines is a critical factor that contributes to their efficiency. With the ability to handle various product sizes and types without extensive reconfiguration, manufacturers can achieve shorter lead times and lower setup costs. According to a recent report by MarketsandMarkets, the global automatic assembly machine market is projected to reach $10 billion by 2026, underscoring the increasing reliance on these technologies to meet production challenges in a dynamic marketplace.

Innovative Technologies Enhancing Precision in Production Lines

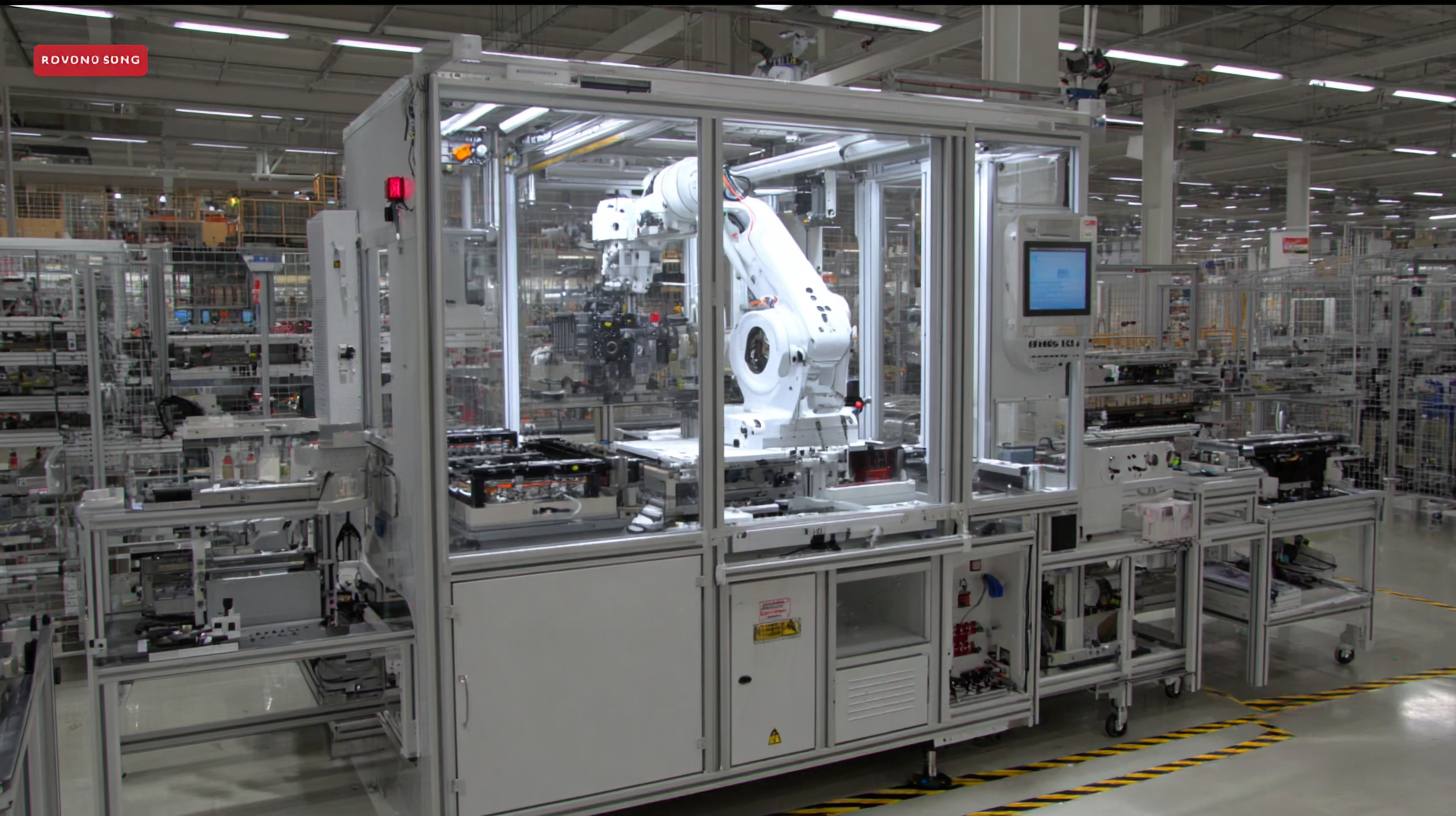

In today's fast-paced manufacturing environment, the integration of innovative technologies into automatic assembly machines is essential for enhancing precision in production lines. Cutting-edge methods such as advanced robotics, machine learning, and computer vision are transforming how products are assembled. These technologies not only streamline operations but also significantly reduce the margin of error, ensuring high-quality output with every cycle.

One essential tip for manufacturers looking to upgrade their assembly processes is to invest in smart automation. Adopting versatile robots equipped with artificial intelligence allows for greater flexibility and adaptability in production. This not only maximizes efficiency but also enables quick adjustments to changing designs without extensive reconfigurations.

Another important aspect to consider is the use of real-time data analytics. By implementing systems that monitor production metrics, companies can quickly identify bottlenecks and inefficiencies. This proactive approach helps in making informed decisions to enhance overall productivity. Regular training for operators on these advanced technologies also plays a critical role in maintaining operational excellence and leveraging the full potential of these innovations.

Cost-Effectiveness: How Investing in Automation Pays Off

In today's fast-paced manufacturing landscape, investing in automation technology proves to be a pivotal strategy for cost-effectiveness. A recent report forecasts the global algorithm trading market is set to reach $2.36 billion by 2024, with projections indicating growth to $2.53 billion by 2025 and $4.06 billion by 2032. This underscores the significant return on investment seen in automated solutions, with an astounding ROI of 1093% highlighted in various industry analyses.

Moreover, organizations are increasingly recognizing that investing in automation does not only enhance production efficiency but also minimizes operational costs in the long run. With the introduction of advanced automatic assembly machines, companies can streamline their operations while maintaining high-quality standards. However, it is crucial to remain mindful of the common pitfalls in IT automation—such as overlooked processes, data quality issues, and integration challenges. These factors, coupled with the regulatory hurdles emerging from AI advancements, require a strategic approach to fully harness the financial benefits of automation investments. By addressing these challenges head-on, businesses can ensure that their investment in automation delivers the promised financial returns.

Scalability and Flexibility: Adapting to Market Demands Seamlessly

In today’s fast-paced manufacturing environment, scalability and flexibility have become paramount for businesses aiming to thrive amid evolving market demands. The best automatic assembly machines are designed with these essential attributes in mind, allowing companies to adapt their production processes to changing consumer preferences without overhauling their entire operation. According to a report by ResearchAndMarkets, the global market for automatic assembly machines is projected to grow at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2028, highlighting an increasing need for adaptable manufacturing solutions.

One of the key innovations in automatic assembly technology is modular design, enabling manufacturers to easily reconfigure their setups. This adaptability means businesses can swiftly pivot their production lines for different products, minimizing downtime and maximizing efficiency. A study by McKinsey indicates that manufacturers who implement flexible automation can reduce their time-to-market by up to 30%, further underscoring the importance of investing in machines that support scalability. As market dynamics continue to shift, those who invest in versatile assembly solutions will be at the forefront, ready to meet new demands with agility.

Safety Standards and Compliance in Modern Assembly Automation

In the realm of modern assembly automation, safety standards and compliance have become paramount. As industries increasingly rely on automatic assembly machines to enhance productivity, the importance of adhering to rigorous safety protocols cannot be overstated. These machines are engineered not only to streamline production but also to protect workers and equipment from potential hazards. Compliance with international safety standards, such as ISO 12100 and ANSI/RIA R15.06, ensures that the machines operate within set parameters, minimizing risks and maximizing efficiency.

Furthermore, manufacturers are integrating advanced technologies to elevate safety in automatic assembly machines. Features such as emergency stop functions, safety interlocks, and real-time monitoring systems are essential in mitigating accidents. Additionally, incorporating sensors and vision systems helps in detecting anomalies, preventing potential malfunctions before they escalate. As assembly automation continues to evolve, ensuring that machines meet stringent safety standards will be critical for fostering a secure working environment and promoting sustainable production practices across various industries.

Revolutionizing Production: Top 5 Technical Specifications of the Best Automatic Assembly Machine

| Specification | Details |

|---|---|

| Production Speed | Up to 1200 units/hour |

| Accuracy | ±0.02mm |

| Power Supply | 220V AC, 60Hz |

| Safety Standards | ISO 12100, CE Marked |

| Control System | PLC with Touchscreen Interface |