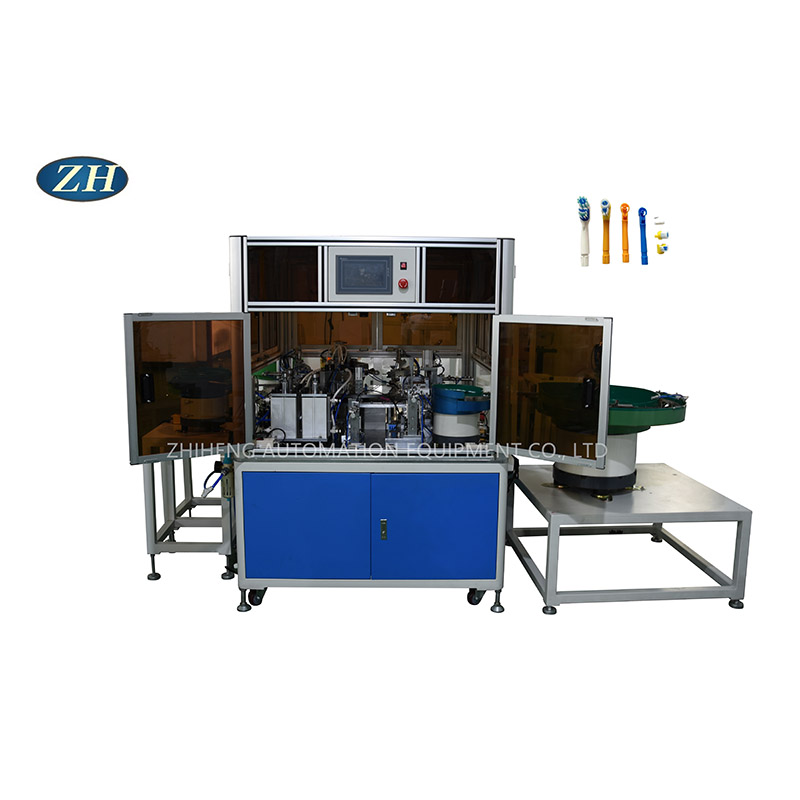

Push-Button Assembly Machine High Precision

Yuyao Zhiheng is one of professional leader China Push-Button Assembly Machine High Precision manufacturers with high quality and reasonable price. Welcome to contact us.Push-Button Assembly Machine is an efficient, accurate and adaptable automation equipment, which plays an important role in the button assembly process. With the continuous progress of technology and the continuous development of the market, the application prospect of the button assembly machine will be broader.

Model:ZH-56

Send Inquiry

Introduction of Push-Button Assembly Machine High Precision:

You can purchase Push-Button Assembly Machine High Precision from Yuyao Zhiheng with confidence, as we are a proficient producer of high-quality Push-Button Assembly Machine High Precision. We promise to provide you with the best after-sale service and prompt delivery.The push-button assembly machine is usually composed of a frame, a distribution control box, a turntable, a turntable drive device and a plurality of assembly mechanisms. Among them, the edge of the turntable is uniformly arranged along the circumference of the base fixture with the controller base, which is used to fix the button base to be assembled. The frame is provided with a base feeding mechanism, a base handling device and a button assembly mechanism to realize the automatic feeding, handling and assembly process.Key components such as the base handling device and the button assembly mechanism use precise transmission and positioning mechanisms to ensure accuracy and stability during assembly.

Parameter (Specification) of Push-Button Assembly Machine High Precision:

1. Automatic feeding base button

2. Detection of base button

3.Automatic feeding plastic pin

4.Automatic feeding Stainless steel plate

5.Automatic assembly the plastic pin and Stainless steel plate

6.Automatic feeding the plastic pin and stainless steel plate assemblies

7.Detection of the plastic pin and stainless steel plate assemblies

8.Automatic feeding reset button

9.Detection of reset button

10.Manual feeding the coil

11.Put the spring into the coil

12.Insert the core into the coil

13.Detection of the spring and core

14.Automatically mounts the assembled coil into the button base

15.CCD check the installation

16.Automatic blanking of good and bad products

Specification,

Power supply:AC 220V /50HZ

Air pressure:above 0.6 MPa

Yield:1500-1800PCS/hour